Cold Traps - Cold Fingers

Construction, Operation And Principles

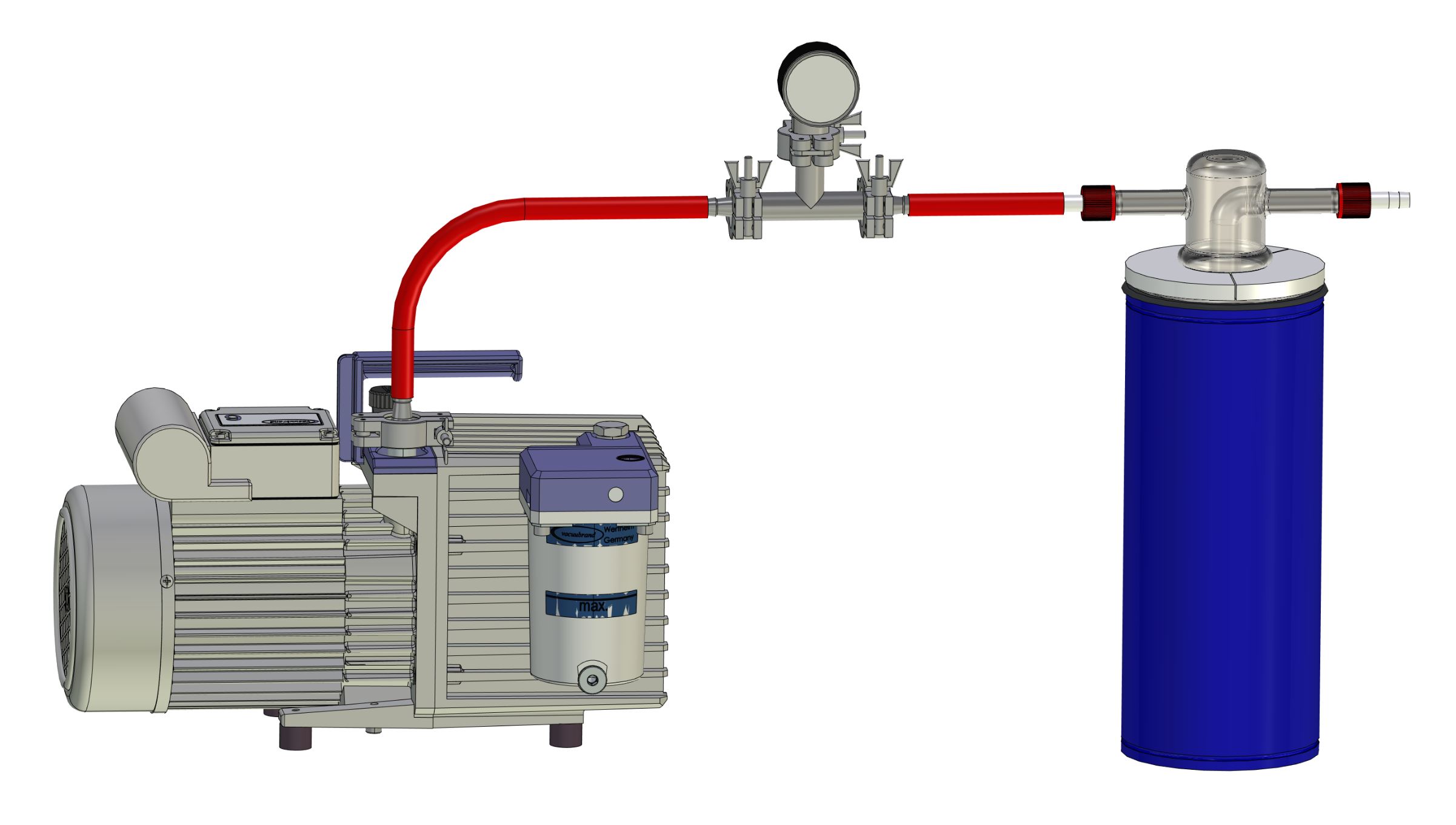

Cold traps are used in conjunction with vacuum pumps to collect condensation produced from humidity or solvents and these cold traps can be used for many different tasks. The most common application is collecting condensation produced from humidity or solvents from rotating discs, vacuum pumps or high vacuum systems that use oil diffusion or turbo-molecular pumps. In this case a common coolant such as liquid nitrogen (LN2) or dry-ice (CO2) with acetone is normally used.

Cold traps can be manufacturer from glass or metal. The use of glass is advantageous in the chemical sector and when producing condensation from solvents, due to its resistance to chemicals. The cold traps listed in our catalogue are produced solely from 3.3-type borosilicate glass, in compliance with DIN/ISO (DURAN made by Schott). The mechanically design takes into account the wall thickness for use under vacuum.

Cold Traps – Different Versions

Simple cold traps, which are also known as cold finger condensers, are used in standard applications in conjunction with vacuum pumps and the condensation is forced out of the humidity or solvents used in the chemical applications. The cold trap is used to protect the vacuum pump in this case and the speciality of this type of construction is that the user does not need to use a stand to hold the cold trap. The cold trap has a rim, which is hung inside the Dewar-flask’s support ring. The cold trap can be changed very quickly without any problems arising.

Cold Traps (Cold Finger Condenser): Long Version

These cold traps are constructed in the same way as standard cold traps. The condensation area in these cold traps has been extended in order to trap a greater quantity of condensation. In addition to this, these complete cold traps also have a larger plastic ring and a bigger Dewar-flask.

Cold Traps Fitted With A Spout

An upgraded version is a cold trap fitted with a spout. These cold traps are constructed in the same way as standard cold traps but have a GL 32 glass thread together with a screw-on cap, which is the actual spout. This spout enables the condensation to be simply poured out of the cold trap and the cold trap is also simple and easy to clean.

Cold Traps: Two Sections, In Standard And Long Versions

A special version is the two section cold trap that is produced in both standard and long versions and has a NS 45/40 taper joint as the connection part. This type of cold trap enables the condensation area to be separated from the upper section of the cold trap. This ensures that the removal of the condensation and the cleaning of the cold traps can be carried out very easily. This version is also suitable for when a cold trap has to be permanently installed inside an apparatus, so that only the lower section of the cold trap has to be removed in order to empty out the condensation. The NS45/40 connecting piece is secured in place using a spring steel clamp and this is included in our scope of delivery.

Cold Traps: Produced To Customer Specifications

The speciality of cold traps made from glass is the number of versions available, which offer a multitude of design options when the mechanical and thermal stresses are taken into consideration and KGW-ISOTHERM specialises in producing customer specific cold traps.

Please send us a drawing or a description and we will work out a proposal together with a drawing.

Technical Data

Cold Trap Catalog as PDF: Download