Cryogenic cooling system Type TG-LKF for cooling applications from +100°C (+212°F) to -180°C (-292°F)

Cryogenic cooling system in sample chambers

To obtain rapid cooling speeds and very low temperatures, sometimes you have to switch from conventional mechanical cooling to cryogenic cooling. With this scenario in mind, KGW-ISOTHERM has developed a new KALTGAS system. In it, a sample chamber is filled with cryogenic nitrogen gas, resulting in a high cooling speed.

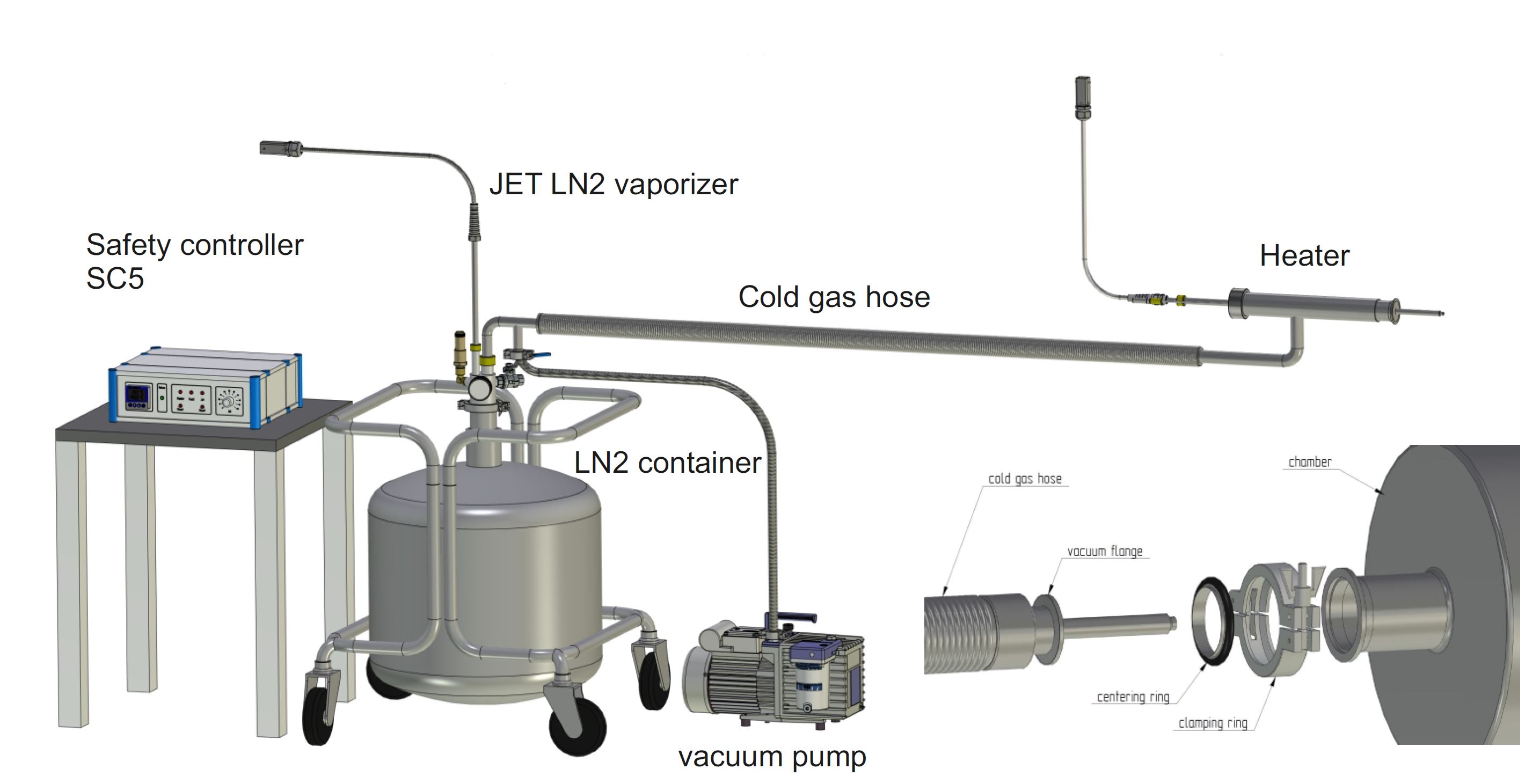

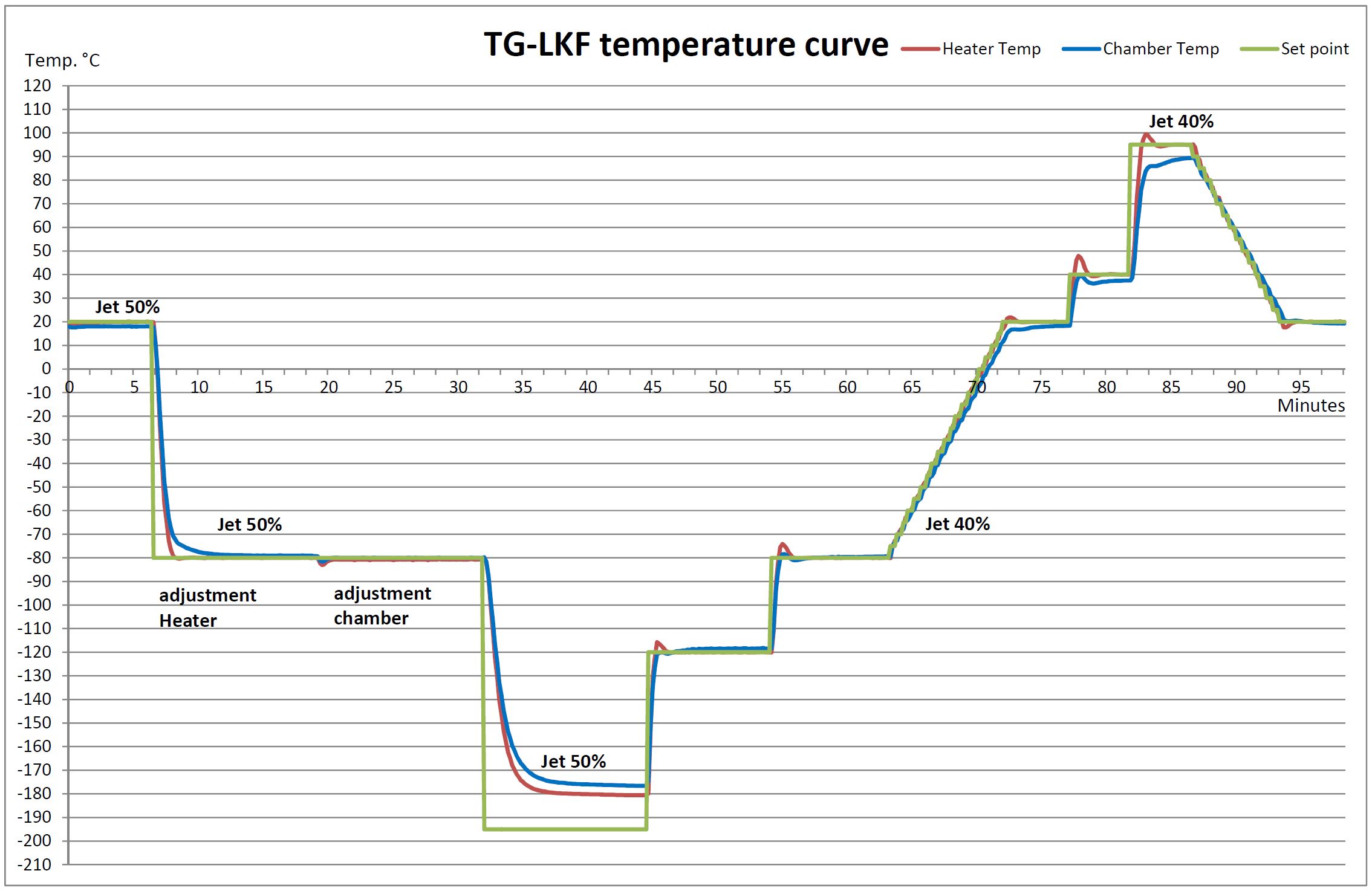

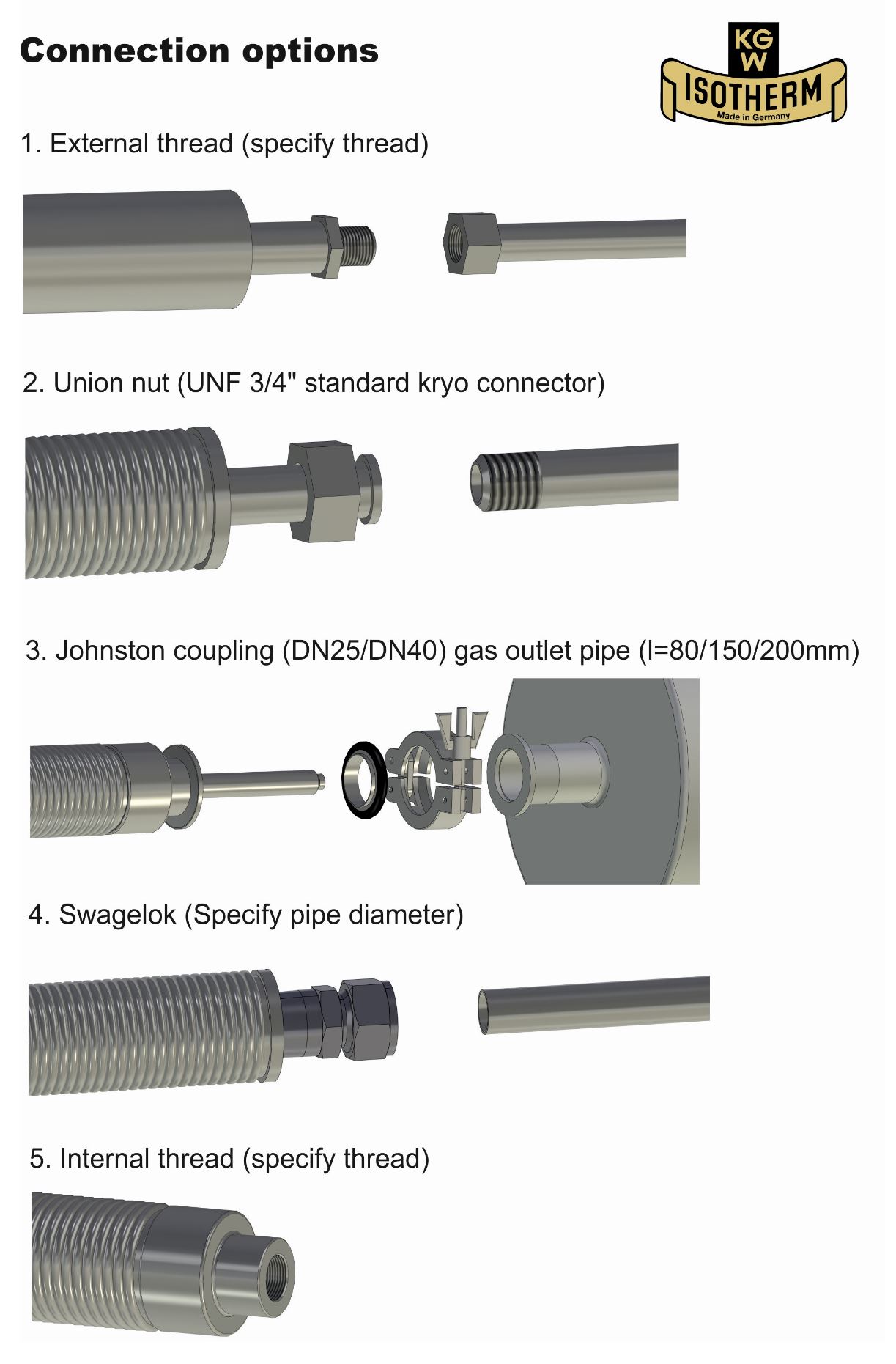

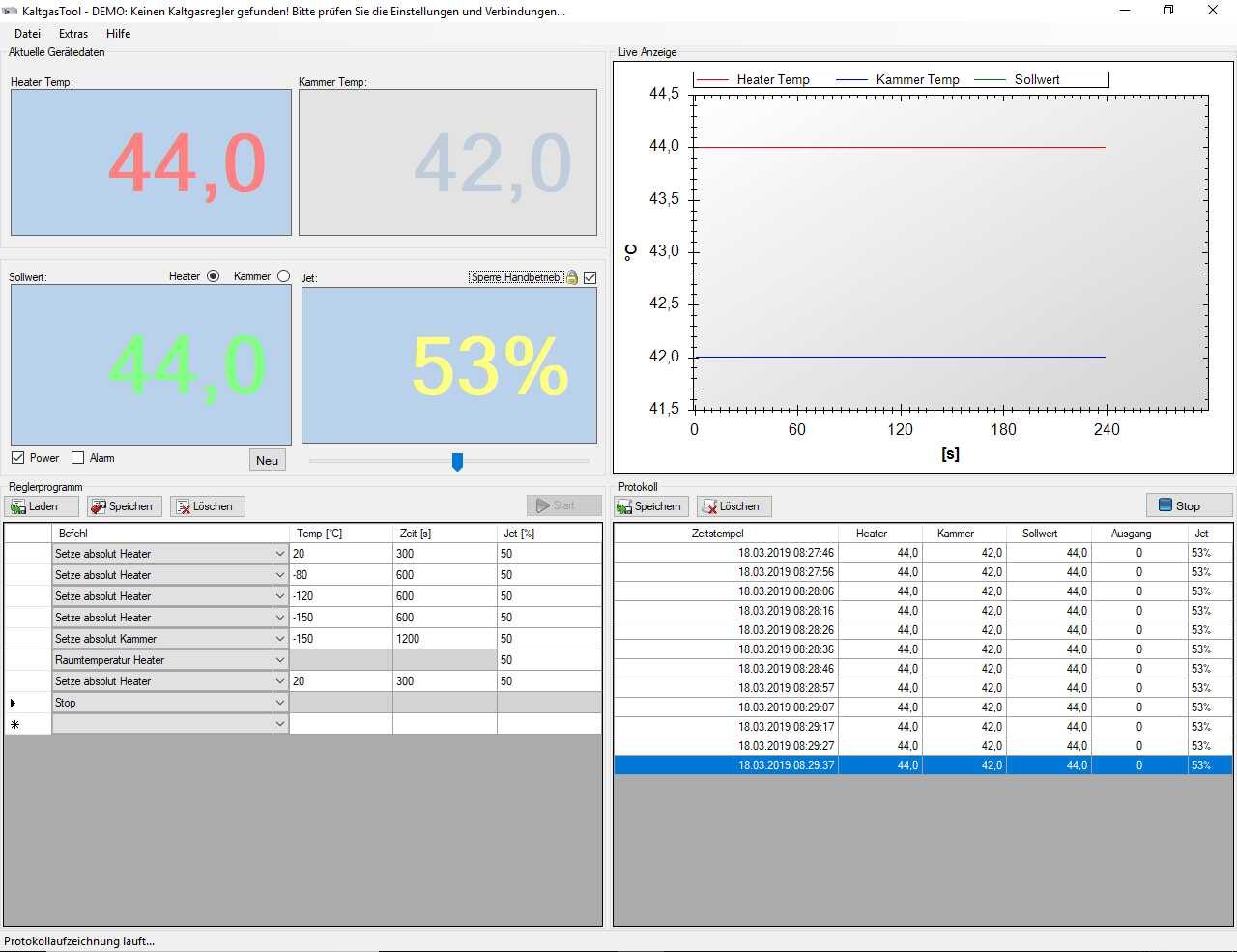

KALTGAS is a tempering system that utilizes the very low temperature of liquid nitrogen as a cooling agent. The Jet vaporizes the liquid nitrogen in a cryogenic container, producing a steady cryogenic gas flow. This LN2 vaporizer (Jet) can be adjusted to minimize liquid nitrogen consumption and to change both the cooling rate and the volume of the gas flow. The cryogenic gas flow is then piped through a vacuum insulated flexible metal line (N2 gas line) to a heat exchanger (heater). The heat exchanger is designed to heat the cold gas flow to the desired temperature. The final product, a clearly quantified gas flow exiting the heat exchanger at a clearly defined temperature, is ready for use as a cooling agent. A KALTGAS system needs only a few minutes to produce a cold gas flow with a temperature of -180°C (-292°F). Configuring the KALTGAS system to any customer's individual environment is possible thanks to various temperature controllers that can be embedded inside the safety control unit. Those temperature controllers are available with or without interfaces. By using an optimized temperature controller, a temperature stability of ± 0.1°C can be achieved. With the standard safety control unit (SC5), a temperature stability of better than ± 0.2°C can be achieved.

The steady gas flow can be used to temper a chamber. Another option is a circulating-air tempering system. It circulates the air in the chamber and cools it with a KALTGAS system type G. This setup enables full utilization of LN2 in temperatures above -20°C (-4°F).

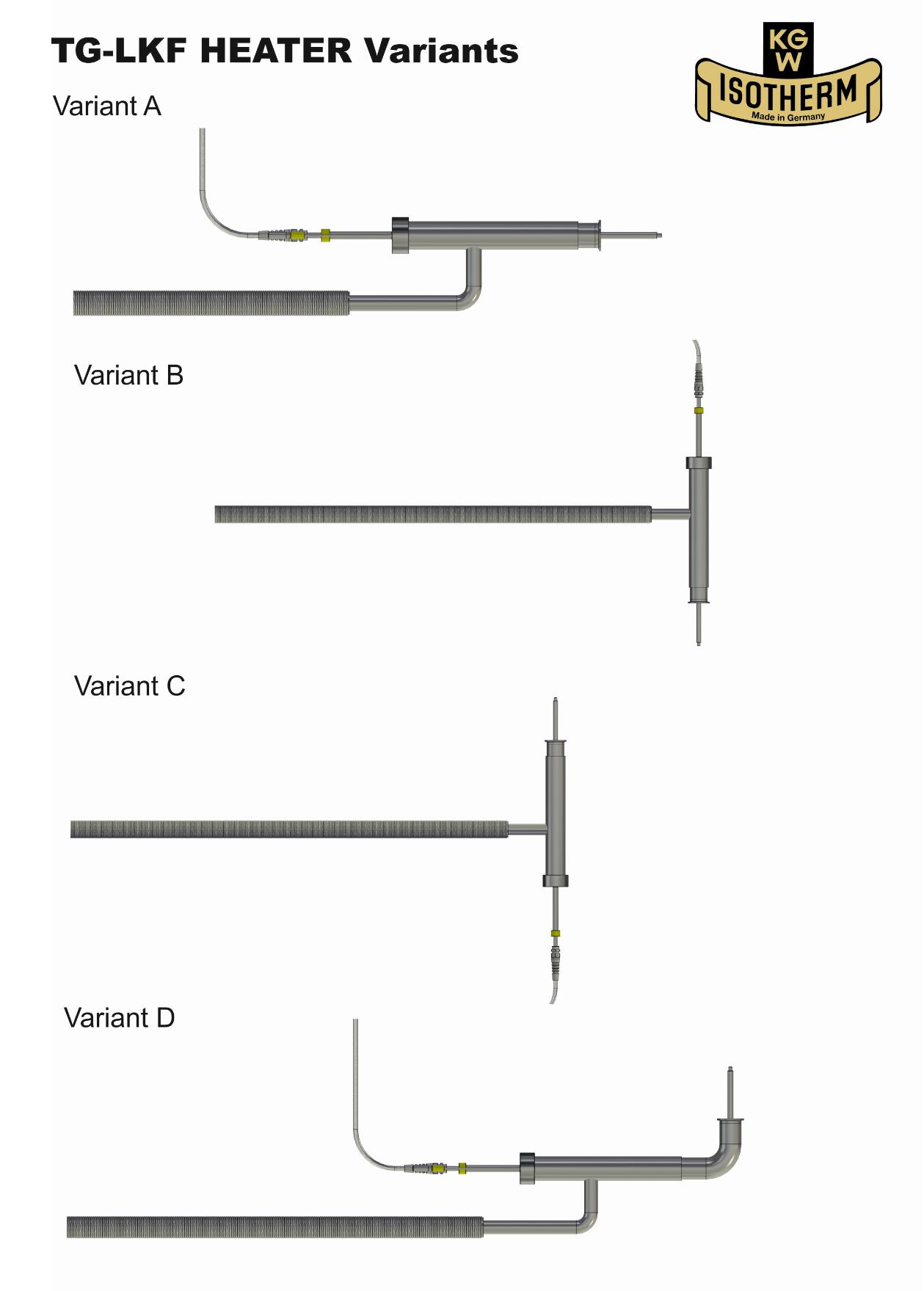

In addition to their high cooling speed and good control stability, another advantage of KALTGAS systems is their modular design. By swapping out individual modules such as the N2 gas line, the LN2 vaporizer (Jet) or the heater, it is possible to change the cooling speed, LN2 consumption as well as the application. The basic modules, including the LN2 container, the vacuum pump and the safety control unit, remain unchanged.

Technical data for

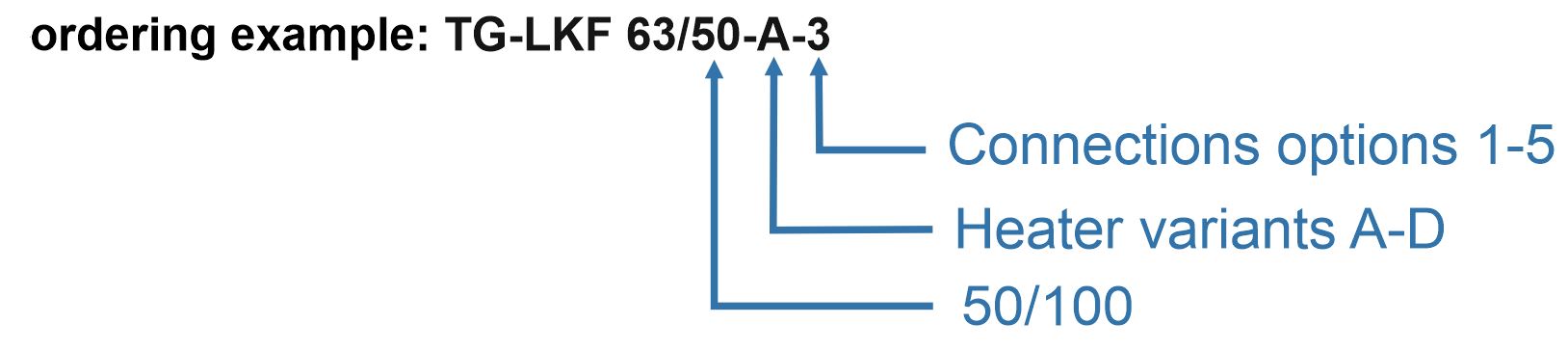

Model TG-LKF 63/50 LN2 vaporizer (Jet)= 500 watts Heater = 630 watts LN2 consumption = 1.1l/h to 11l/h (liters per hour) N2 gas line = V2A, length 1.8 meters, flexible, with vacuum pump siphon for LN2 container with KF NW 50 Order No.: TG-LKF 63/50

Model TG-LKF 63/100 LN2 vaporizer (Jet)= 1000 watts Heater = 630 watts LN2 consumption = 2.2l/h to 22l/h (liters per hour) N2 gas line = V2A, length 1.8 meters, flexible, with vacuum pump siphon for LN2 container with KF NW 50 Order No.: TG-LKF 63/100

Accessories

LN2 container with 20 to 300 liter capacity Further information on KALTGAS systems available. Technical data subject to change.Download Kaltgas information sheet

- Kaltgas information sheet as PDF-Format Download Kaltgas information sheet

Download Kaltgas TG-LKF sample manual

- Kaltgas sample manual as PDF-Format Download Kaltgas TG-LKF sample manual