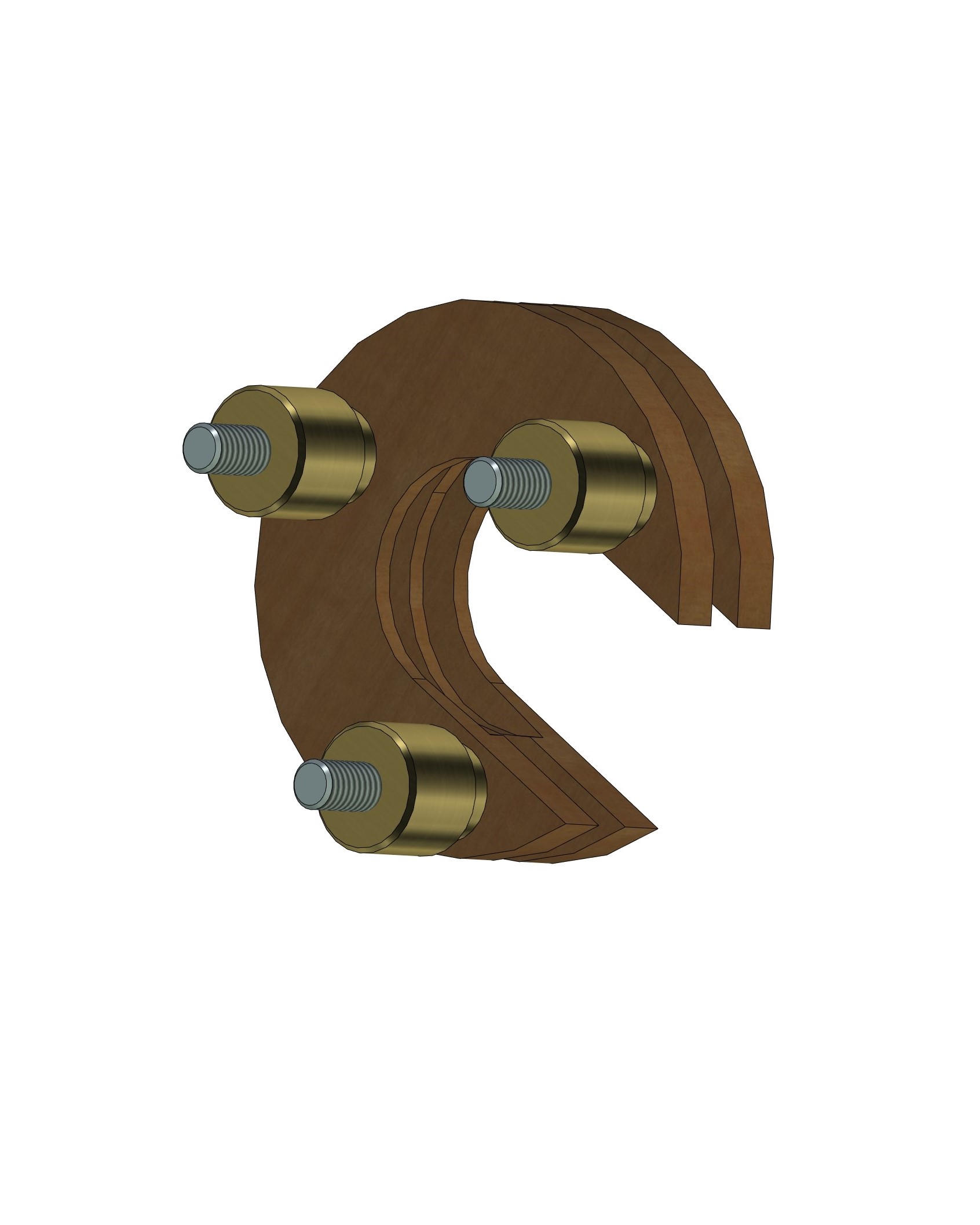

Pump fork / Schlenklines

Applications

- gas cleaning by condensation e.g in vacuum systems

Versions

- HV = Higher vacuum tightness

- K = spherical joint S29

- OK = spherical joint S29 with O-ring sealing

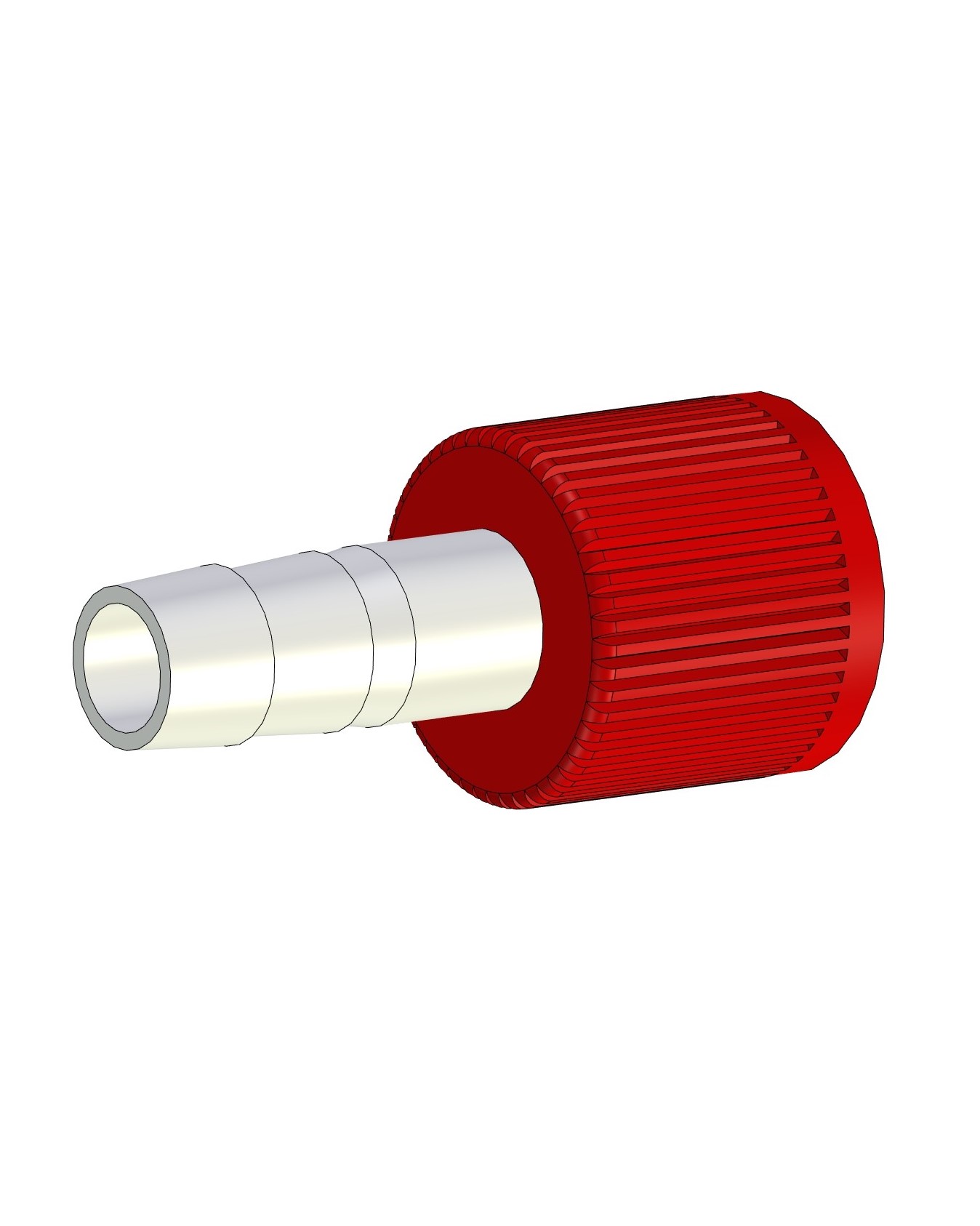

- GL= Glass screwthread with olive GL18

- NW= Vacuum flange

- special dimensions

- special connections

Advantages

- made of Borosilicatglas 3.3

- good chemical resistance

- good thermal resistance

- simple low cost design

- quick exchange is possible

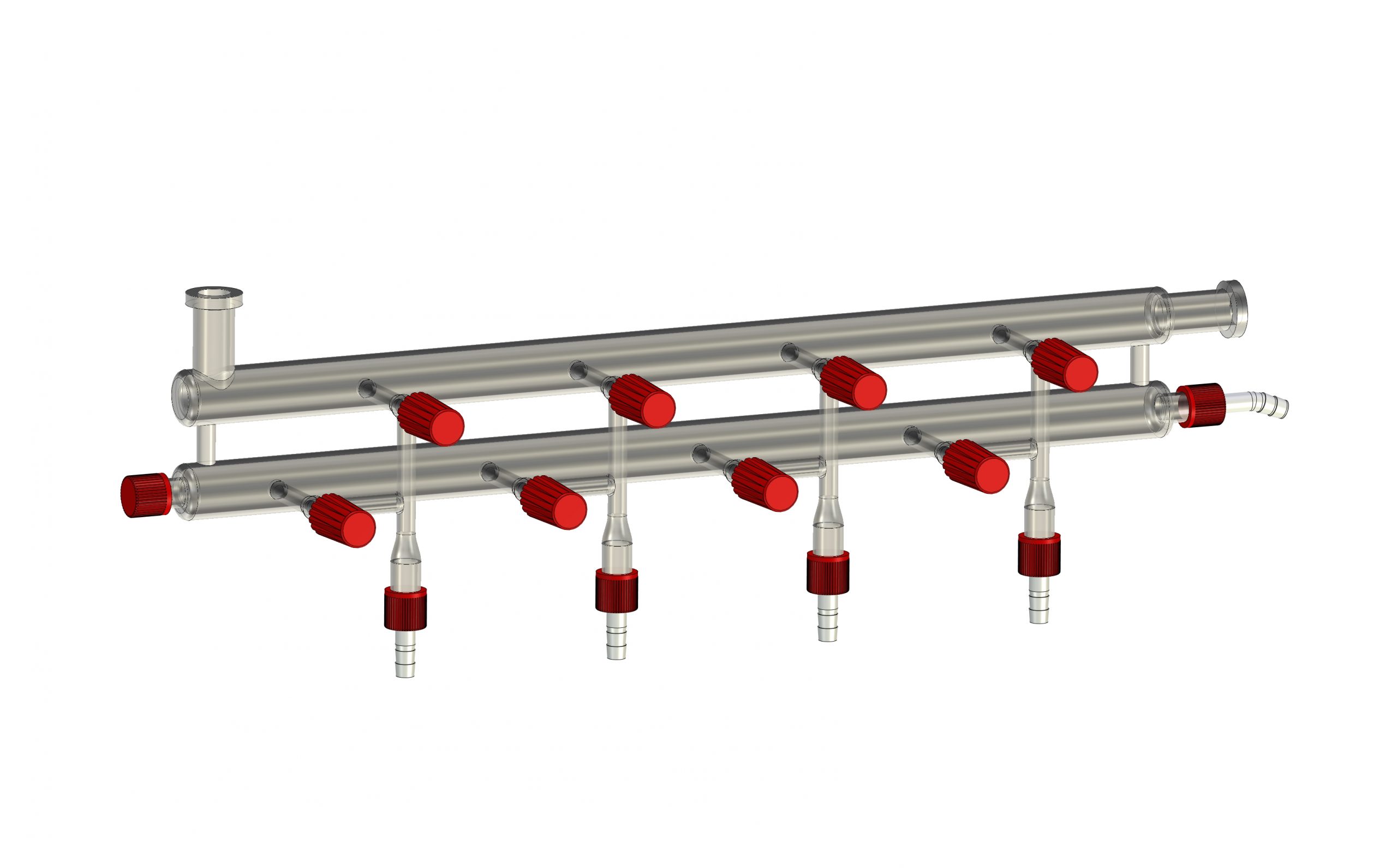

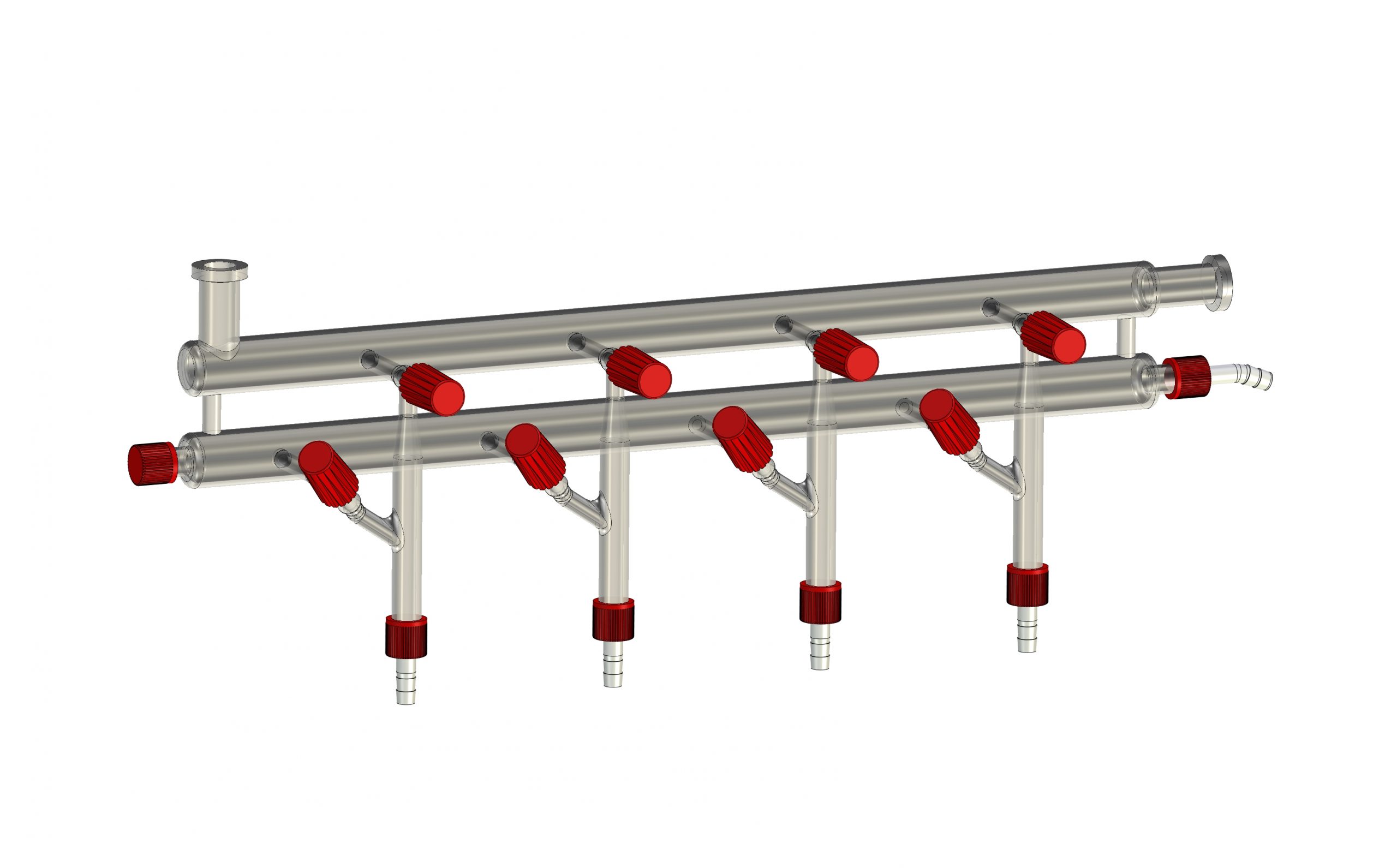

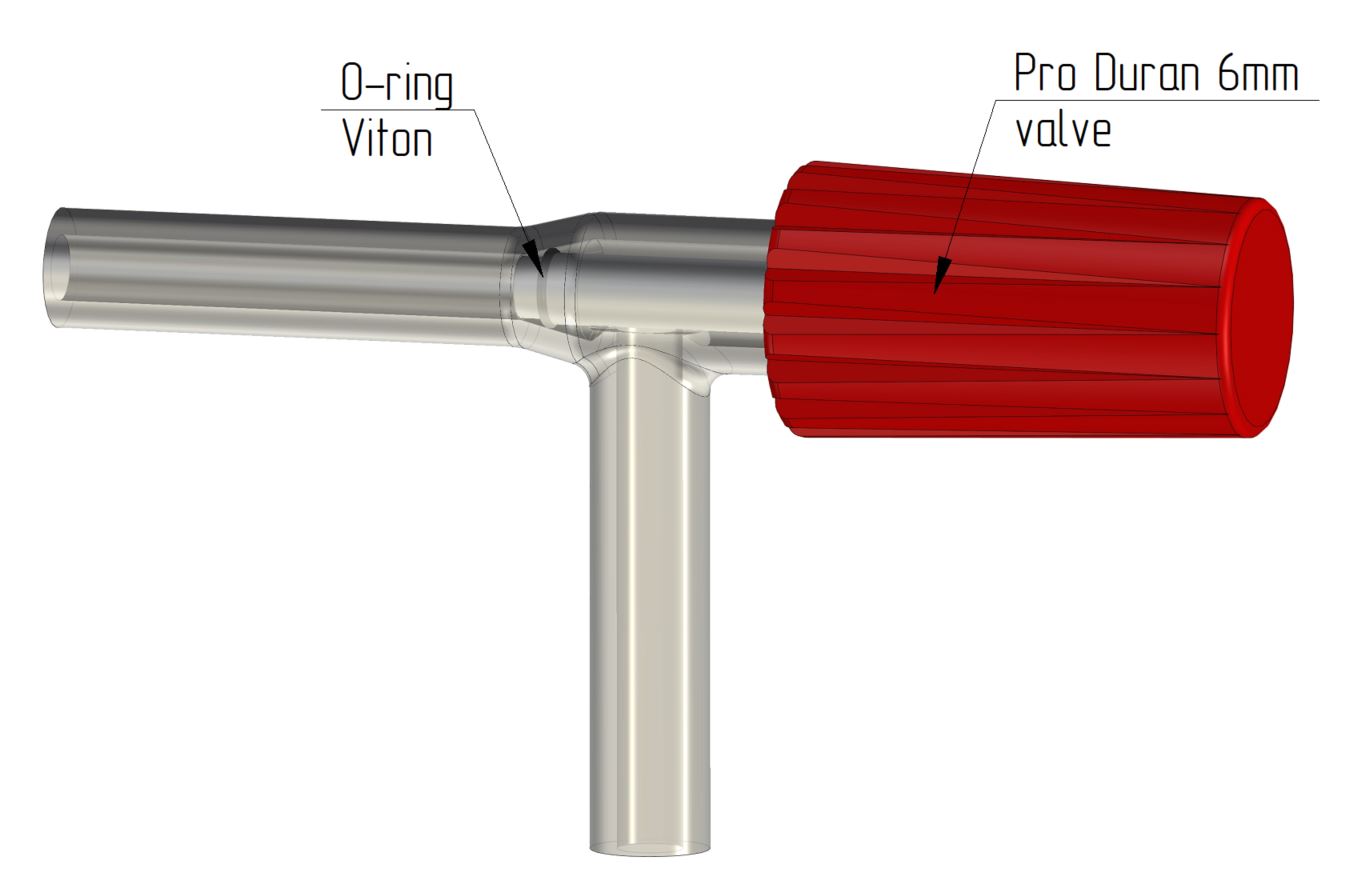

Pump forks / Schlenklines for chemical pump stands are customer’s specific accessories, the construction of which depends on the user's requirements. The user stipulates the number of drainage valves as well as the position of the vacuum-measuring flange and fumigating or ventilation valves can also be fitted. Modified Schott Produran valves are used as valves.To increase the vacuum tightness, these valves will additionally be provided with an O-ring seal in the valve seat.

Technical Data pump forks

| Type | Connection vacuum pump | Connection outlets | lateral connection outlets | Article. No. |

|---|---|---|---|---|

| pump fork with aeration | KF NW16 | 4 x GL18 with olive | 1x GL18 with sealing cap / 1x GL18 with weird olive | 17631 |

| pump fork HV with aeration | KF NW16 | 4 x GL18 with olive | 1x GL18 with sealing cap / 1x GL18 with weird olive | 17631-HV |

| pump fork with aeration | KF NW16 | 5 x GL18 with olive | 1x GL18 with sealing cap / 1x GL18 with weird olive | 17633 |

| pump fork HV with aeration | KF NW16 | 5 x GL18 with olive | 1x GL18 with sealing cap / 1x GL18 with weird olive | 17633-HV |

Accesories / Spare parts

| Discription | Artikel No. |

|---|---|

| GL 18 olive | 17331 |

| Pertinax-screw connection KF 10/16 | 17315 |

| Pertinax-screw connection KF 20/25 | 17316 |

| centerring ring KF 10/16 | 17320 |

| centerring ring KF 20/25 | 17321 |

| Spare part drain valve | 17701 |

| Replacement o-ring Viton | 17702 |

Technical data sheet

Download cold trap catalog

- Cold trap catalog as PDF-format: Download cold trap catalog