Kaltgas System

Kaltgas - Low temperature cooling system for cooling applications from max. +100°C (212°F) up to -180°C (-292°F)

What is Kaltgas

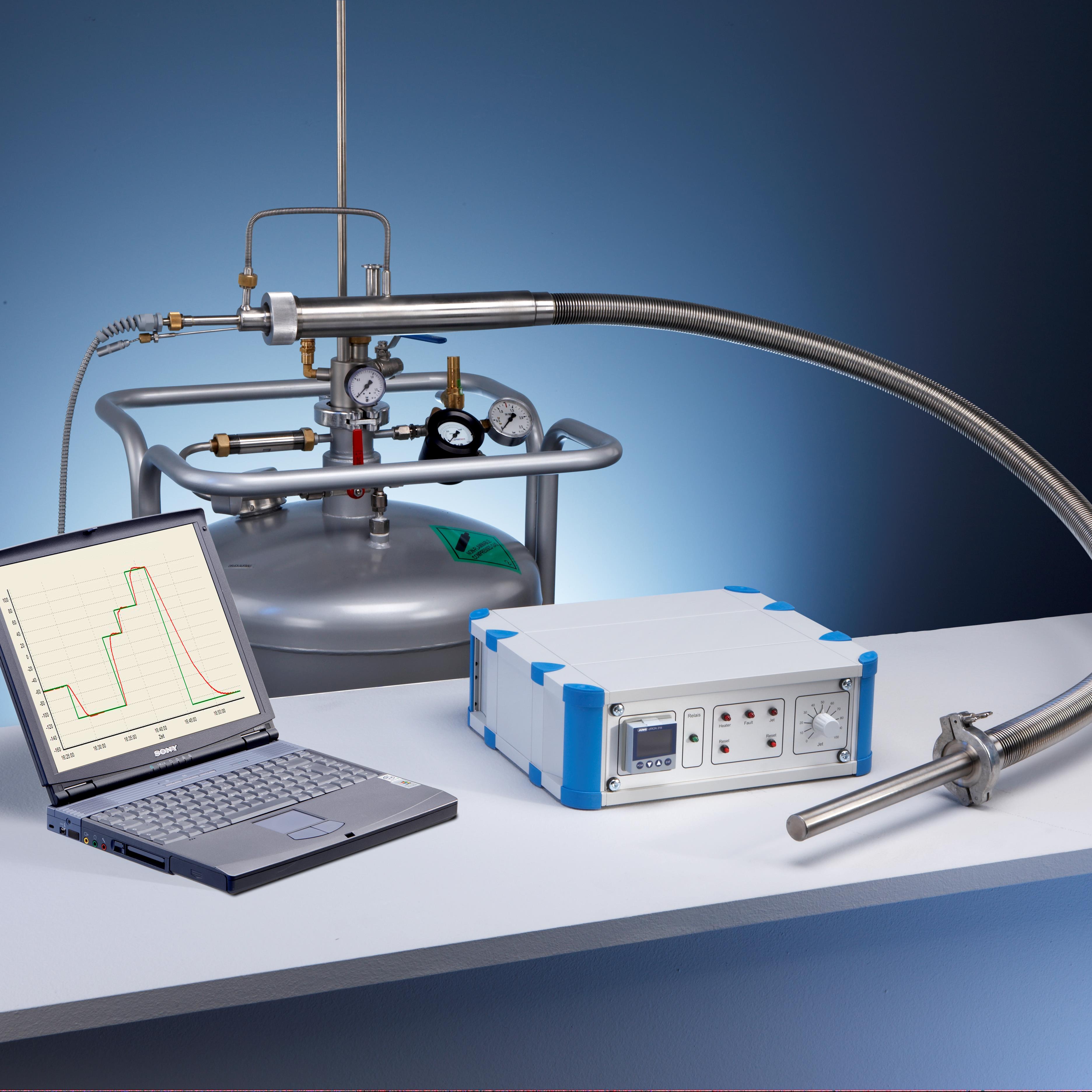

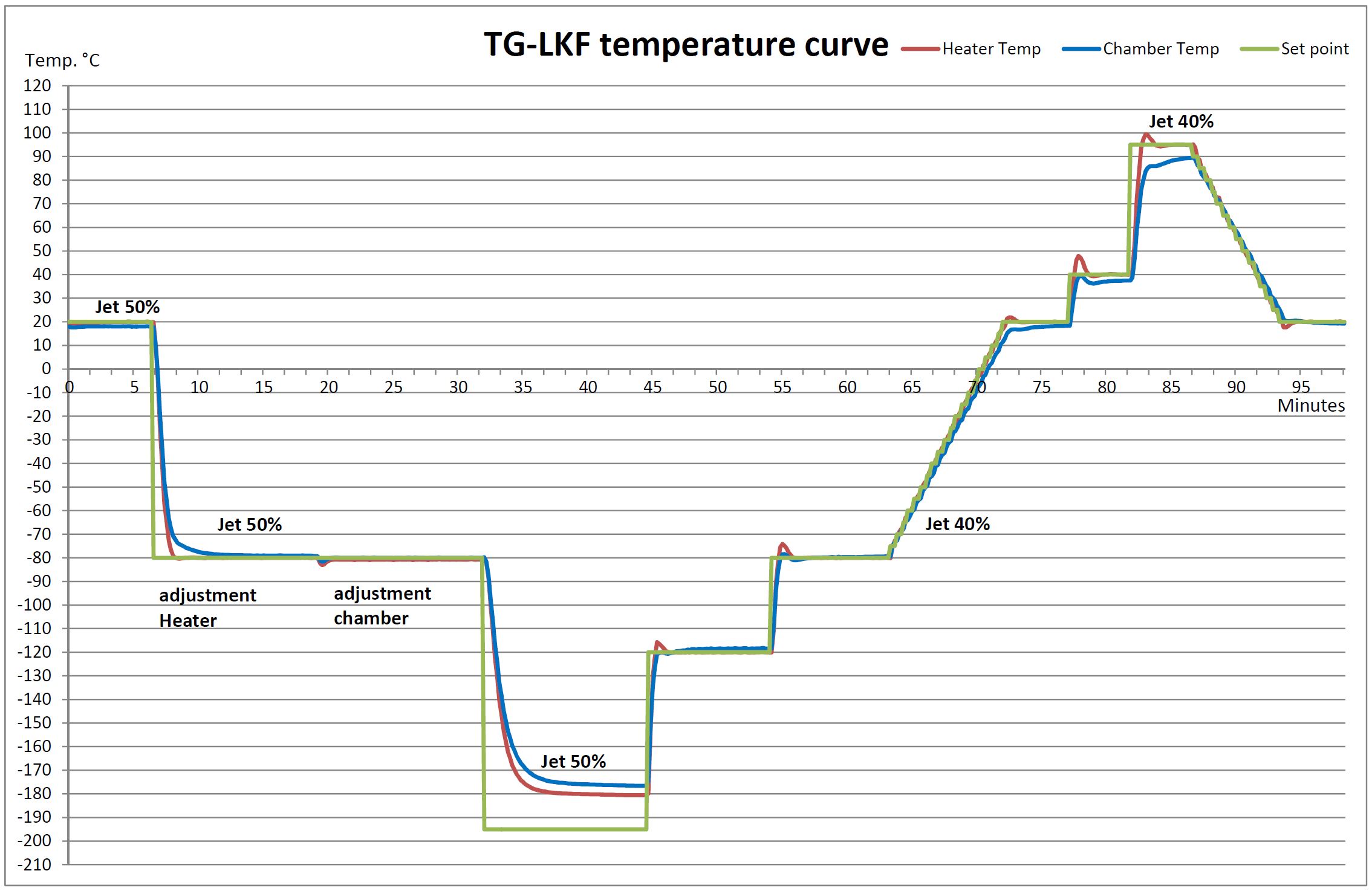

KALTGAS is a tempering system that utilizes the very low temperature of liquid nitrogen as a cooling agent. The Jet vaporizes the liquid nitrogen in a cryogenic container, producing a steady cryogenic gas flow. This LN2 vaporizer (Jet) can be adjusted to minimize liquid nitrogen consumption and to adjust both the cooling rate and the volume of the gas flow. The cryogenic gas flow is then piped through a vacuum insulated flexible metal line (N gas line) to the object you wish to cool. A KALTGAS system needs only a few minutes to produce a cold gas flow with a temperature as low as -180°C (-292°F).

In most cases, this KALTGAS system is only used to produce a cold gas flow. The volume of the gas flow is adjusted with the safety control unit. Since the controlled system operates without a heat exchanger, it is not possible to maintain precise temperature stability.

To achieve good temperature and control stability, a post-heating module (heat exchanger) must be installed. This module can be connected directly to the line, or installed in a chamber right next to the cold gas flow. The heat exchanger is designed to heat the cold gas flow to the desired temperature. The final product, a clearly quantified gas flow exiting the heat exchanger at a clearly defined temperature, is ready for use as a cooling agent. With the safety controller SC5, a temperature stability of better than ±0.2°C can be achieved at a steady state.

Apart from the high cooling speed, another advantage of KALTGAS systems is their modular design. By swapping out individual modules such as the N gas line, the LN2 vaporizer (Jet) or the heater, it is possible to change the cooling 2 speed, LN2 consumption as well as the application. The basic modules, including the LN2 container, the vacuum pump and the safety control unit, remain unchanged.

Fields of application

- Thermal testing of plastics, metals, composites etc.

- Cooling of electronic components

- Cooling of sample chambers

- Rapid freezing of biological samples, food and other materials

-

Tempering of test samples during

- Tension or torsion tests

- Notched bar tests

- Chemical or physical tests

- Chemical engineering processes

Download Kaltgas Katalog

- Kaltgas Catalog as PDF-FileDownload Kaltgas Catalog

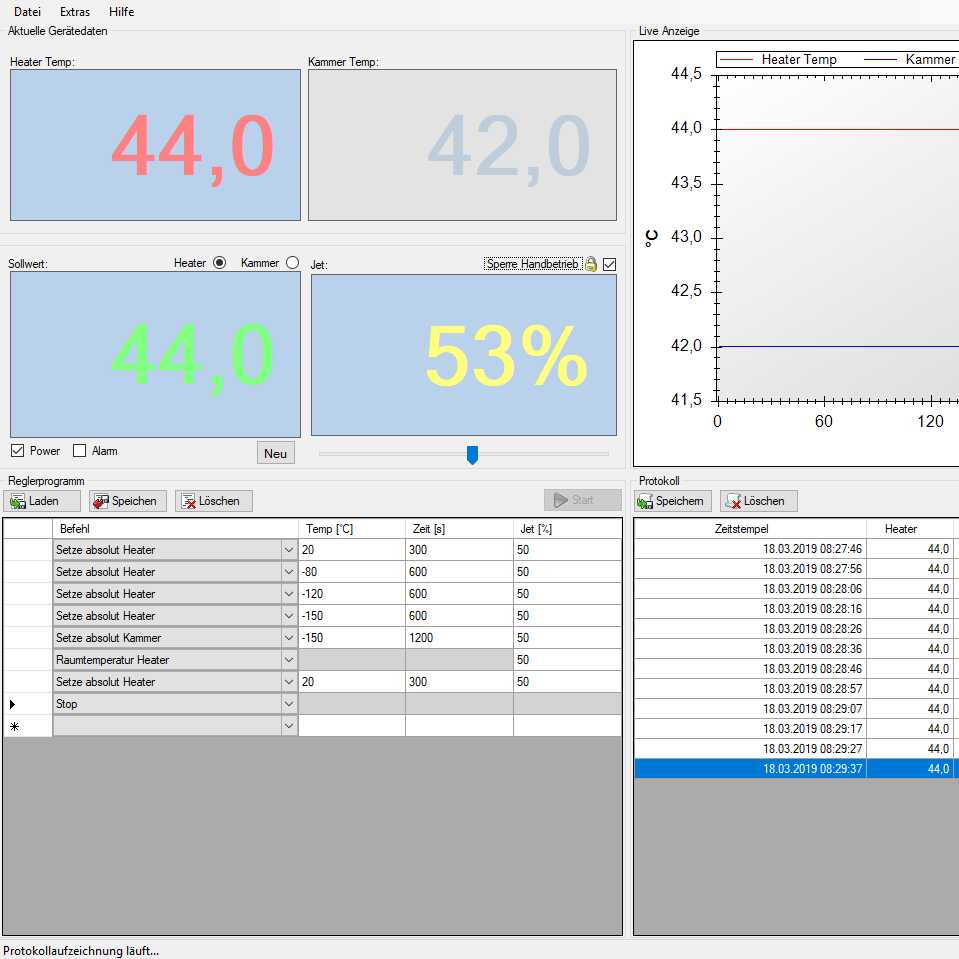

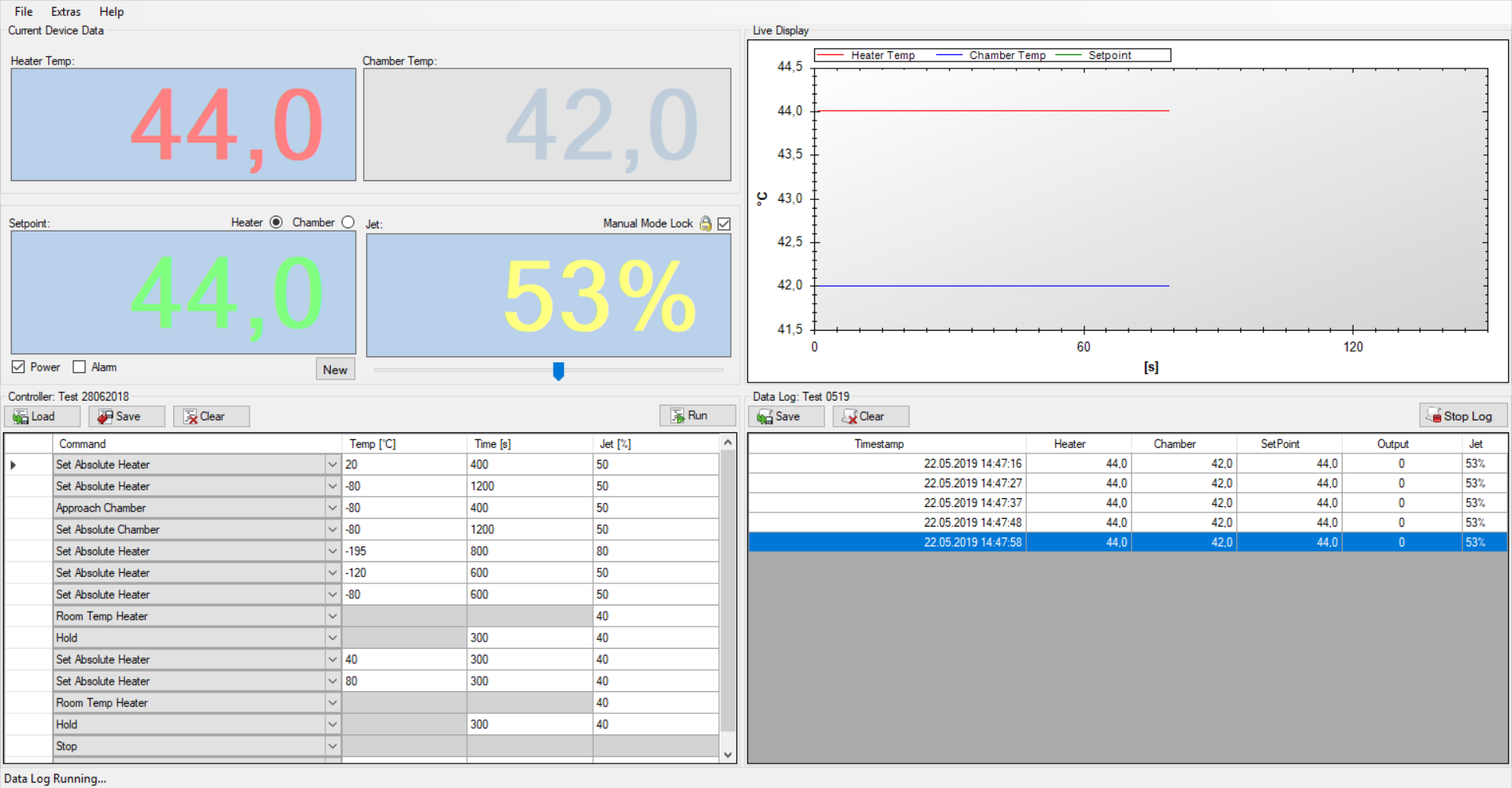

KaltgasTool

Software for Controlling Kaltgas SystemsDownload KaltgasTool and Manual

Configuration Wizzard for Kaltgas Systems Configuration Wizzard for cold kaltgas system.