Columns

Application

Advantages

Executions

KGW-ISOTHERM

offers two different vacuum-insulated column types in its column catalog. These are packed columns and Vigreux columns. Both column types are used for different applications. The columns on offer are all double-walled, vacuum-insulated and silver-plated. Vacuum insulation and silver plating result in improved and more reproducible separation behavior, as this considerably reduces the heat input from the ambient temperature. The vacuum reduces the contact heat and the silver plating reduces the radiant heat.

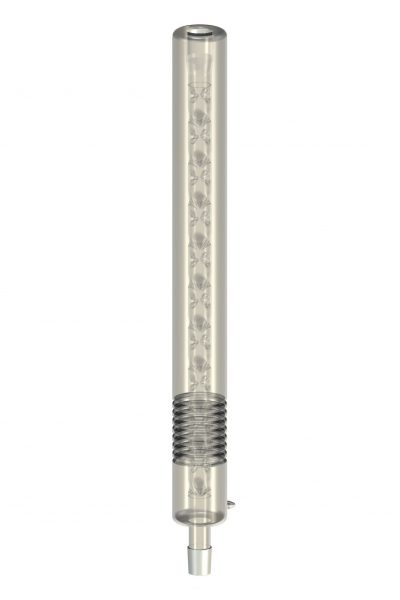

Vigreux columns

The Vigreux column is a typical laboratory device. The column is used in rectification, commonly known as fractional distillation, to improve the thermal separation of liquid mixtures. The contact surface between the gas phase and the glass is considerably increased by the slightly downward sloping indentations.

The Vigreux column is often used for vacuum distillation (distillation at reduced overall pressure in the distillation plant). Vacuum distillation lowers the boiling temperatures of the individual components, which enables the distillation of substance mixtures whose components remaining in the sump are not sufficiently temperature-stable. At higher temperatures, the sump or the remaining reactant may contain catalyst residues or by-products that reduce the yield due to undesirable reactions.

Packing columns

The Vigreux column is a typical laboratory device. The column is used in rectification, commonly known as fractional distillation, to improve the thermal separation of liquid mixtures. The contact surface between the gas phase and the glass is considerably increased by the slightly downward sloping indentations.

The Vigreux column is often used for vacuum distillation (distillation at reduced overall pressure in the distillation plant). Vacuum distillation lowers the boiling temperatures of the individual components, which enables the distillation of substance mixtures whose components remaining in the sump are not sufficiently temperature-stable. At higher temperatures, the sump or the remaining reactant may contain catalyst residues or by-products that reduce the yield due to undesirable reactions.