Automatic level control systems

for liquid nitrogen

Automatic level control of liquid nitrogen in a Dewar vessel

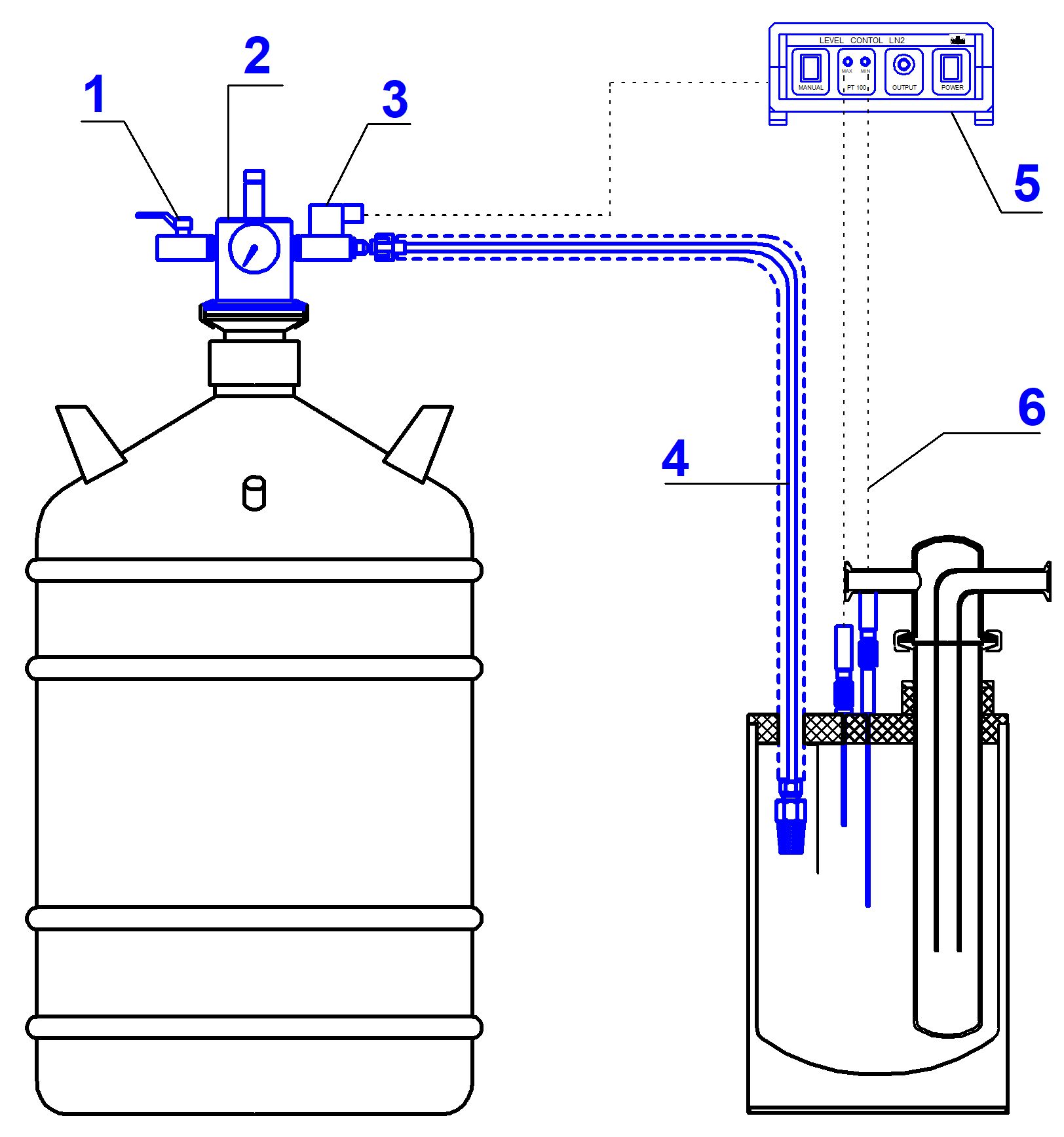

In many cryogenic applications, such as shrinking shafts and bushings in LN2, deep-freezing components or biological samples, using LN2 as a coolant in cold traps, calibrating sensors in LN2, etc., it is important to maintain a constant LN2 liquid level. This can be achieved with the LN2 Level Control from KGW-ISOTHERM. With this LN2 Level Controller, the LN2 level can be set between a minimum and a maximum sensor and kept constant. The KGW-ISOTHERM LN2 Level Control can be connected to almost any LN2 tank.

The LN2 level control works as follows:

If the LN2 level falls below the minimum sensor, a signal is sent to the level controller. The level controller then opens a 24 volt LN2 solenoid valve, which is connected to the removal siphon of the LN2 storage container. The excess pressure in the LN2 storage tank forces the LN2 out of the tank and through a transfer line to the working dewar vessel. The LN2 flowing into the working dewar vessel raises the liquid level until the maximum sensor is immersed in the LN2. This cools down the maximum sensor and sends a signal to the level controller. This then de-energizes the solenoid valve so that it closes and interrupts the LN2 supply. If the LN2 level has fallen below the minimum sensor again after some time, the process described above is repeated.

Automatic LN2 level control for manual shrinking devices

To ensure manual or automatic connections by shrinking, it is important that sufficient cooling of the components to be shrunk is always guaranteed. When shrinking bushes or shafts, LN2 is usually used as a coolant. An automatic LN2 level control system ensures the necessary cooling by means of LN2. This ensures that the shrink fit functions reliably.

Automatic LN2 level control for manual shrinking devices with two holders for the bushings to be shrunk, Dewar flask, lid, exhaust pipe and a 35 liter LN2 container. Best. No. 2760-35

- LN2 Storage container

- Siphon with solenoid valve

- Transfer line

- LN2 Level Controller

- Exhaust pipe

- Socket holder

- Minimum/maximum sensor

- Bushing to be shrunk

- Working Dewar vessel

Automatic LN2 level control for cold trap applications

To ensure the condensation performance of a cold trap, it is important to maintain a largely constant LN2 liquid level in the Dewar flask. This constant LN2 liquid level ensures that the entire condensate freezing wall of the cold trap is always functional and that the usable volume of the cold trap can therefore be utilized.

Automatic LN2 level control with a glass cold trap type SL29-GL-A, Dewar flask, lid, exhaust pipe and a 25 liter LN2 container. Best. No. 2755-25

- LN2 Storage container

- Siphon with solenoid valve

- Transfer line

- LN2 Level Controller

- Exhaust pipe

- Socket holder

- Minimum/maximum sensor

- Bushing to be shrunk

- Working Dewar vessel

Level control device for liquid nitrogen type LEVEL CONTROL

Download manual PDF: Manual for LN2 Level Control

Application

LEVEL CONTROL LN2

Advantages

Item number

| Product | Type | Item no. |

|---|---|---|

| LN2 Withdrawal siphon with solenoid valve for storage container with safety fitting | TYPE 1 | 1304L |

| LN2 Withdrawal siphon with solenoid valve for storage container without safety fitting | TYPE 2 | 1305L |

| Solenoid valve for liquid nitrogen (LN2 DC) | 24V | 1303-DC |

| Electrical connection cable, two-piece for solenoid valve | 1302L-K2 | |

| PT100 sensor with cable | 1302L | |

| PT100 sensor metal-encapsulated (specify length) | 1302ML length | |

| Connection cable to the metal-encapsulated sensor | 1302M-KL |

- Pressure release valve

- LN2 Removal siphon

- Solenoid valve for LN2 (24V)

- PTFE removal tube (8×1)

- Nevea control unit

- Min. and max. sensor (PT 100)

Download PDF:

Operating instructions Level Control LN2

Safety time limiter for automatic LN2 level control systems