Low-temperature cooling system type T-G for small and large cooling capacities down to -180°C

Low-temperature cooling system for cooling applications down to -180°C

This KALTGAS system is designed for a temperature range down to -180°C, in which the temperature control system is only designed to generate a cold gas flow. The low temperatures are achieved by using cold nitrogen gas. The liquid nitrogen is vaporized in the LN2 storage tank and is thus available as a cold gas for temperature control. This constant, cold gas flow can be used, for example, to blow on the object to be cooled or to direct the gas flow into a test chamber for cooling.

Application examples

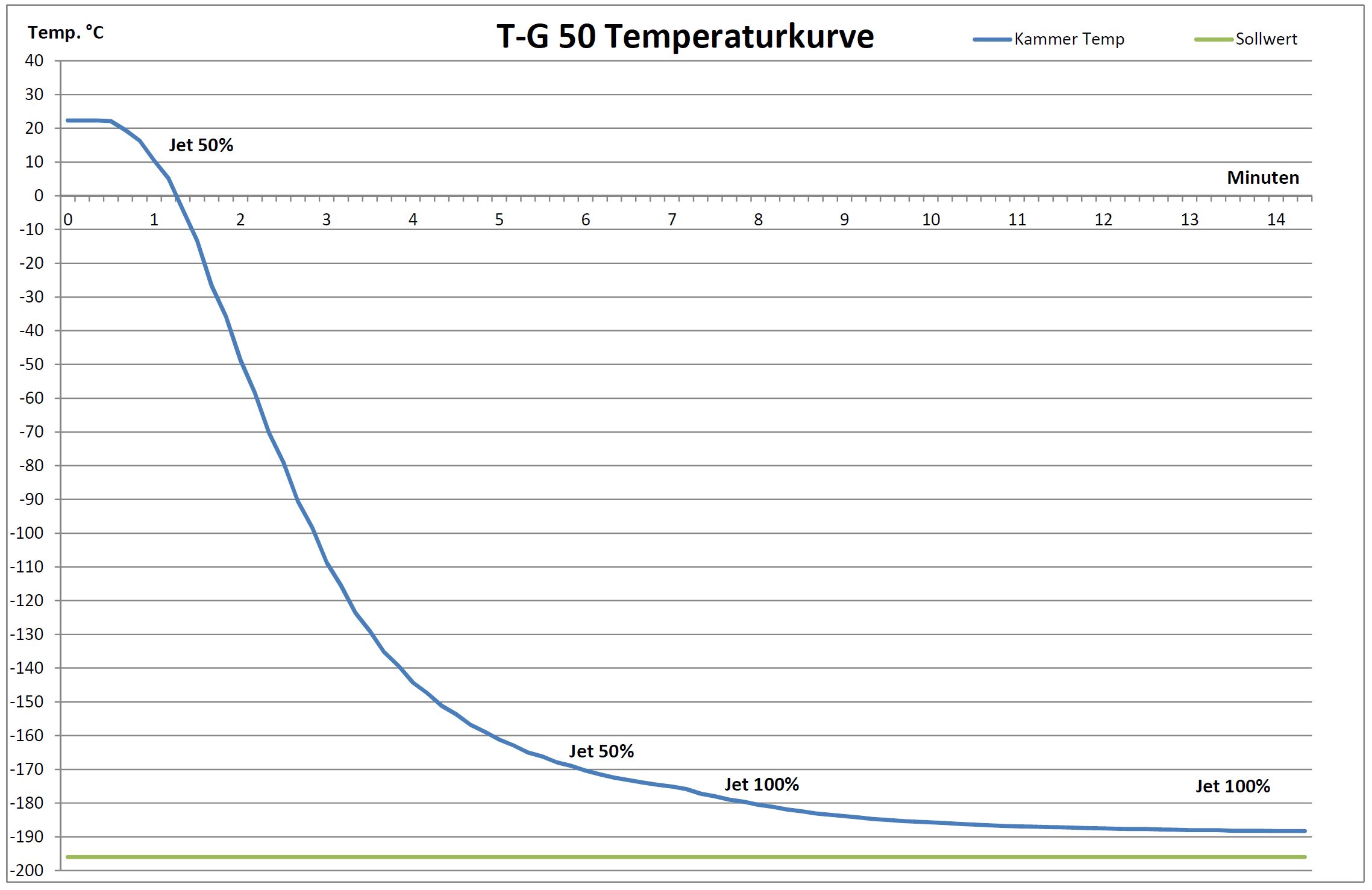

KALTGAS is a temperature control system based on the low temperature of liquid nitrogen as a refrigerant. The liquid nitrogen is vaporized in a cryogenic tank by means of a heater (jet). This generates a constant, cryogenic gas flow. By varying the heater (jet) on the safety power controller (SL1), both the cooling capacity and the gas flow volume can be changed, and the LN2 consumption can be reduced to the necessary minimum by varying the jet power. The cryogenic gas flow is then fed through a vacuum-insulated, flexible metal pipe to the object to be cooled. A KALTGAS system can generate a cold gas flow of up to -180°C within a few minutes. In most cases, this KALTGAS system is only used to generate the cold gas flow. This gas flow can be controlled in terms of volume via a power regulator. As this type of controlled system operates without counter-heating, temperature control is not possible. In order to achieve temperature and control stability, a reheating module ( heater – heat exchanger ) must be used. This can be mounted directly on the hose, or it can be installed in a chamber in the immediate vicinity of the cold gas flow. The reheating module (heater) has the task of heating the cold gas flow to the desired temperature. This means that a predefined gas flow with a predefined temperature is available as a coolant at the outlet of the heat exchanger. In addition to the high cooling speed, the modular design is another advantage of KALTGAS systems. By replacing individual components, such as the N2 gas line, the jets or the heaters, the cooling rate or the LN2 consumption, as well as the type of use, can be changed. The basic modules, such as the LN2 tank, vacuum pump or temperature control, remain unchanged.

Technical data

Technical data for

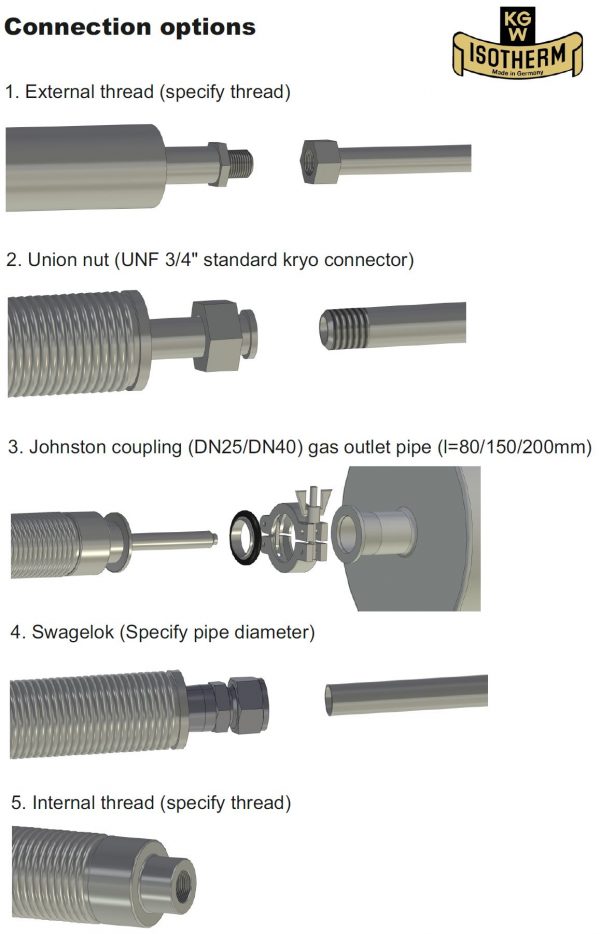

Type T-G50 / Jet = 500 Watt / LN2 Consumption = 1.1 l/h to 11 l/h (liters per hour) Pipe V2A, length 1.8 meters, can be evacuated with vac. Pump lifter for LN2 container with KF NW 50 Order no. No.: T-G 50-1 (external thread) Order no. No.: T-G 50-2 (union nut) Order no. No.: T-G 50-3 (Johnston clutch) Order no. No.: T-G 50-4 (Swagelok) Order no. No.: T-G 50-5 (female thread)

Download cold gas info sheet

Cold gas info sheet as PDF file Download cold gas info sheet

Download cold gas T-G sample manual

Cold gas sample manual as PDF file Download cold gas T-G sample manual

Accessories

LN2 containers from 20 liters to 300 liters volume Post-heating module Other KALTGAS system services on request Subject to technical changes