Compact low-temperature cooling system type TG-KKK for temperature chambers made of glass or metal from +100°C to -180°C measured at the internal temperature sensor

Compact cryogenic cooling for small sample chambers from +100°C to -180°C

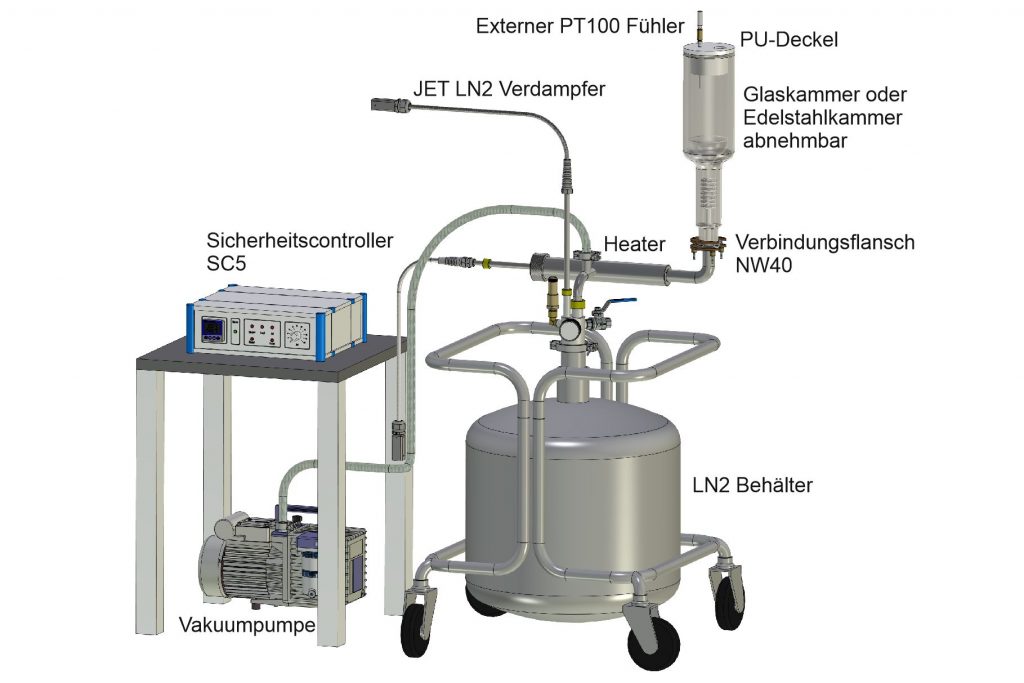

In order to meet the requirements for fast cooling speeds and low temperatures, it is sometimes necessary to switch from conventional thermostat cooling to liquid gas cooling. KGW-ISOTHERM has developed a new KALTGAS application for this application. Here, a test chamber is cooled using cryogenic nitrogen gas, enabling rapid cooling to low temperatures. The cold gas system is very compact and has a flange connection to connect different chambers made of glass or metal directly to the gas outlet nozzle.

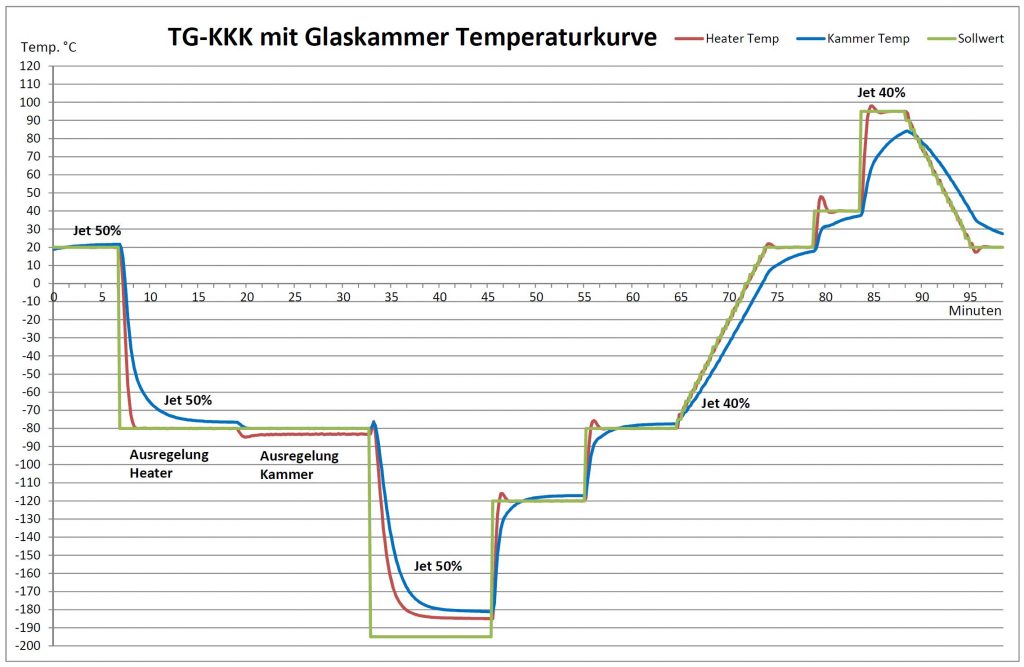

KALTGAS is a temperature control system based on the low temperature of liquid nitrogen as a refrigerant. The liquid nitrogen is vaporized in a cryogenic container using a heater (jet). This generates a constant, cryogenic gas flow. By varying the heater (jet) on the safety controller (SC5), both the cooling capacity and the gas flow volume can be changed, and the LN2 consumption can also be reduced to a minimum by varying the jet power. The cryogenic gas flow is then fed through a vacuum-insulated metal pipe to a heat exchanger (heater). The heat exchanger has the task of heating the cold gas flow to the desired temperature. This means that a predefined gas flow with a predefined temperature is available as a coolant at the outlet of the gas outlet nozzle. A KALTGAS system can generate a -180°C cold gas flow within a few minutes. The use of different temperature controllers enables the optimum customized design of a KALTGAS system. Depending on the customer’s requirements, temperature stability of up to +/-0.1°C can be achieved by using the optimum controller. With a standard safety controller (SC5), a temperature stability of less than +/-0.2°C is achieved.

This constant gas flow can be used to temper a chamber flanged onto the system.

In addition to the high cooling speed and good control stability, the modular design is a major advantage of KALTGAS systems. A wide variety of parts, such as probes, electrical components or test tubes, can be tempered by exchanging the temperature chamber.

The cold gas system type TG-KKK 63/50 consists of a temperature controller with actual and setpoint value display, a safety controller and interface, a KF-NW 50 siphon with LN2 vaporizer (jet), an evacuable, compact N2 gas assembly with built-in reheating module (heater) and a PT100 temperature sensor, as well as a vacuum pump with accessories.

The cold gas system type TG-LKF-H 63/50 consists of a temperature controller with actual and setpoint value display, a safety controller, a KF-NW 50 siphon with LN2 vaporizer (jet), an evacuable, flexible N2 gas line with built-in reheating module (heater) and a PT100 temperature sensor, as well as a vacuum pump with accessories.

Technical data for:

Type TG-KKK 63/50

(Heater = 630 watts / Jet = 500 watts / LN2 consumption approx. 1.1 l/h to 11 l/h liters per hour

Piping V2A, gas outlet nozzle = KF NW 40, evacuatable with vac.

Pump

Siphon for LN2 container with KF NW 50)

Order no. No. TG-KKK 63/50

Download cold gas info sheet

Cold gas info sheet as PDF file Download cold gas info sheet

Accessories

Further KALTGAS system services on request

Subject to technical changes