Low-temperature cooling system type TG-RD for glass reaction vessels Temperature range from +100°C to -180°C measured at the internal temperature sensor

Cryogenic cooling for reaction vessels down to -180°C

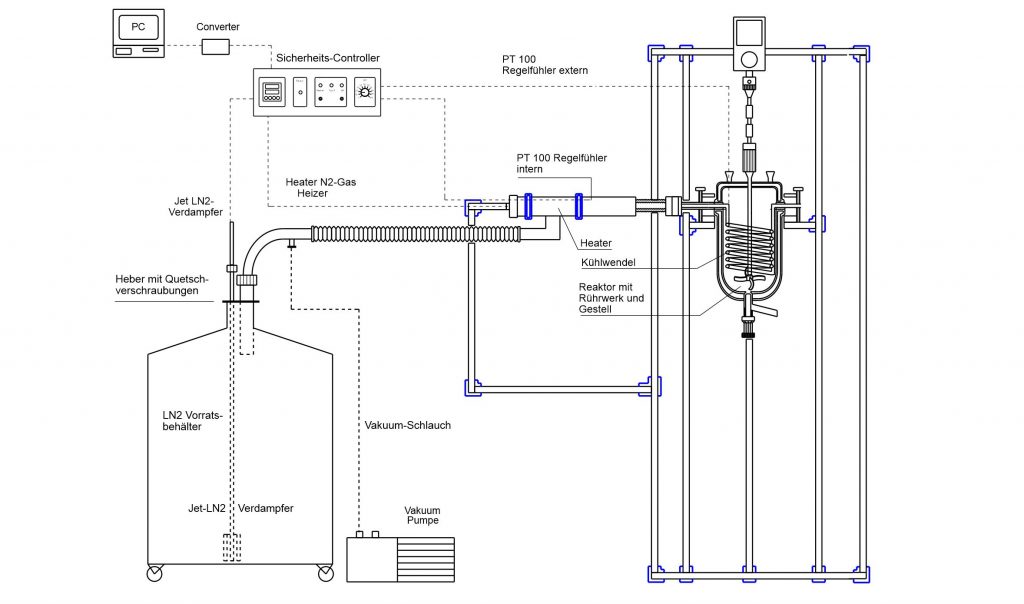

In order to meet the requirements for fast cooling speeds and low temperatures, it is sometimes possible to switch from conventional thermostat cooling to liquid gas cooling. KGW-ISOTHERM has developed a new KALTGAS application for this application. Here, the reactor is cooled using cryogenic nitrogen gas, thus enabling high cooling speeds.

In addition to the high cooling speed and good control stability, another major advantage of KALTGAS systems is their modular design. By replacing individual components, such as the gas line, the jet or the heater, both the cooling capacity and the cooling speed can be changed. The basic modules, such as the LN2 tank, vacuum pump or temperature control, remain unchanged. Another advantage is the reaction vessel. This can also be fitted with a drain valve in this design. As the temperature is controlled using nitrogen gas, the reaction vessel can be changed without the usual problems associated with thermostatic oil. The cleaning of the reaction vessel is limited to the reaction chamber of the vessel and no longer to the additional cleaning of the tempering jacket.

In a reaction vessel, 1.5 liters of methanol are cooled from +20°C to -95°C within approx. 50 minutes. The LN2 consumption during the cooling phase is 5 – 6 liters of LN2. To keep the methanol at -95°C, the reactor only requires approx. 1.2 liters of LN2 per hour.

Technical data for:

Type TG-RD

Jet = 500 watts

Heater = 400Watt

Reactor = 2 liter volume vacuum-insulated with a viewing strip

Lid = 3 x NS 29/32 lateral / central 1 x NS 29/32 ; vacuum-insulated

Frame made of aluminium

Piping made of V2A, length 1.5 meters, evacuable with vac. Pump

Siphon for LN2 container with KF NW 50

Order no. No.: TG-RD 40/50

Download cold gas info sheet

Cold gas info sheet as PDF file Download cold gas info sheet

Accessories

LN2 containers with volumes from 20 liters to 300 liters

Agitator, stirrer and stirrer cap

Reactors with larger volumes

Further KALTGAS system services on request

Subject to technical changes