Cold expansion of components using customized products

Cold shrinking with LN2

- Application

- Advantages

- Executions

- Products for cold stretching

- Cold expansion of components of all kinds thanks to custom-made products

- Examples of sample baskets / sample holders

- Examples of shrink levels for manual LN2 filling

- Example shrink stand with automatic LN2 filling

- Example shrink stand with automatic LN2 filling and customized work table according to customer specifications

Creating high-strength metal joints without compromising on quality or reworking: cold stretching is a simple and proven process for joining components together with a positive fit and in a short space of time. This technology is based on the physical law that metals contract – “shrink” – at cold temperatures. If the components are then reheated, they expand and thus create a firm hold. The advantages of cold stretching – also known as cold shrinking – are obvious:

- Low labor and energy costs

- Applicable almost everywhere

- No loss of quality

- Precisely fitting and firm connections

- Can be combined with heat treatment

The optimum equipment

Liquid nitrogen is suitable for achieving the low temperature required for cold stretching. Suitable, high-quality and certified equipment is mandatory when handling liquefied gas. We offer you a range of high-quality products in series production, but also accessories manufactured specifically to your specifications for your area of application.

Application

Advantages

Executions

Products for cold stretching

Dewar flasks: Our Dewar flasks are made of borosilicate glass 3.3 (DIN/ISO 3585) in accordance with the current ISO standard 16496 for Dewar flasks. The double-walled vacuum-insulated containers are suitable for insulating liquid nitrogen or another coolant against the ambient temperature. The protective coating is made of stainless steel, aluminum or a PU coating. Depending on the size and shape of the components to be processed during cold expansion, KGW-Isotherm offers vessels with different dimensions and volumes. Of course, we can also produce containers according to your specifications, for example for particularly large or multiple components.

Transport and storage containers: To store liquid nitrogen or another coolant safely, transport it easily and be able to dose it at any time, we recommend our high-quality stainless steel or aluminium storage containers with different capacities and the option of customizing them for your purposes with our add-on parts and designs.

Sample baskets: We manufacture individual sample holders/baskets in the appropriate size specifically for your applications.

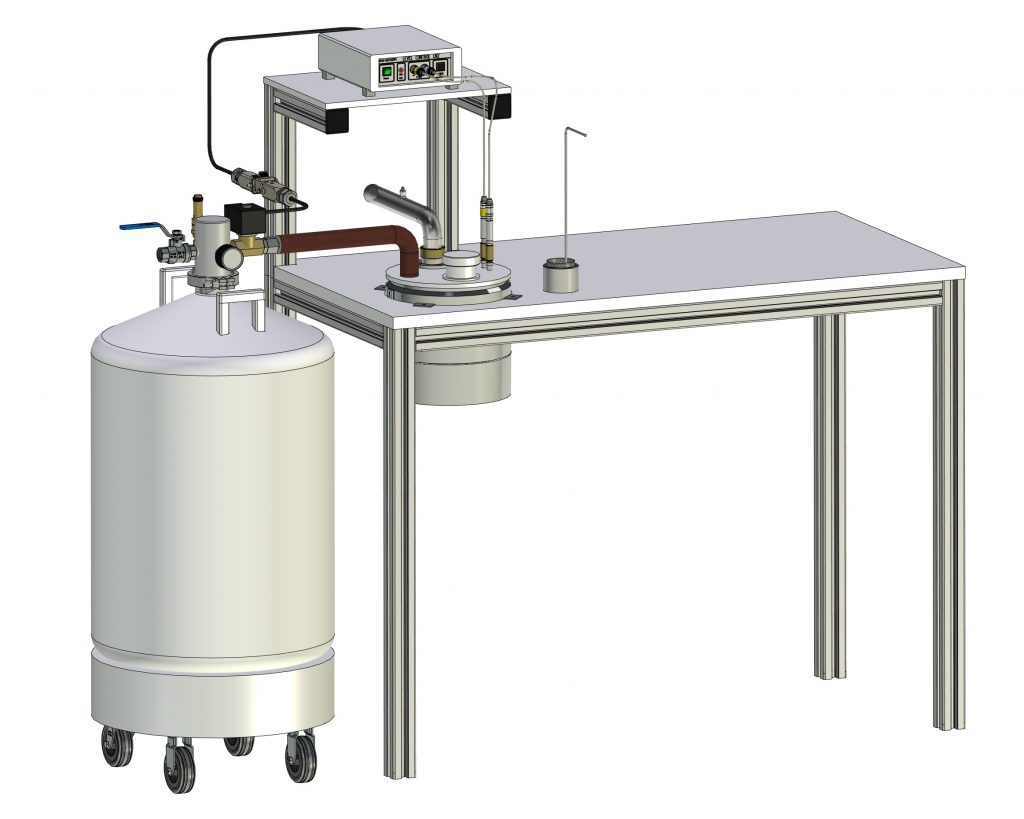

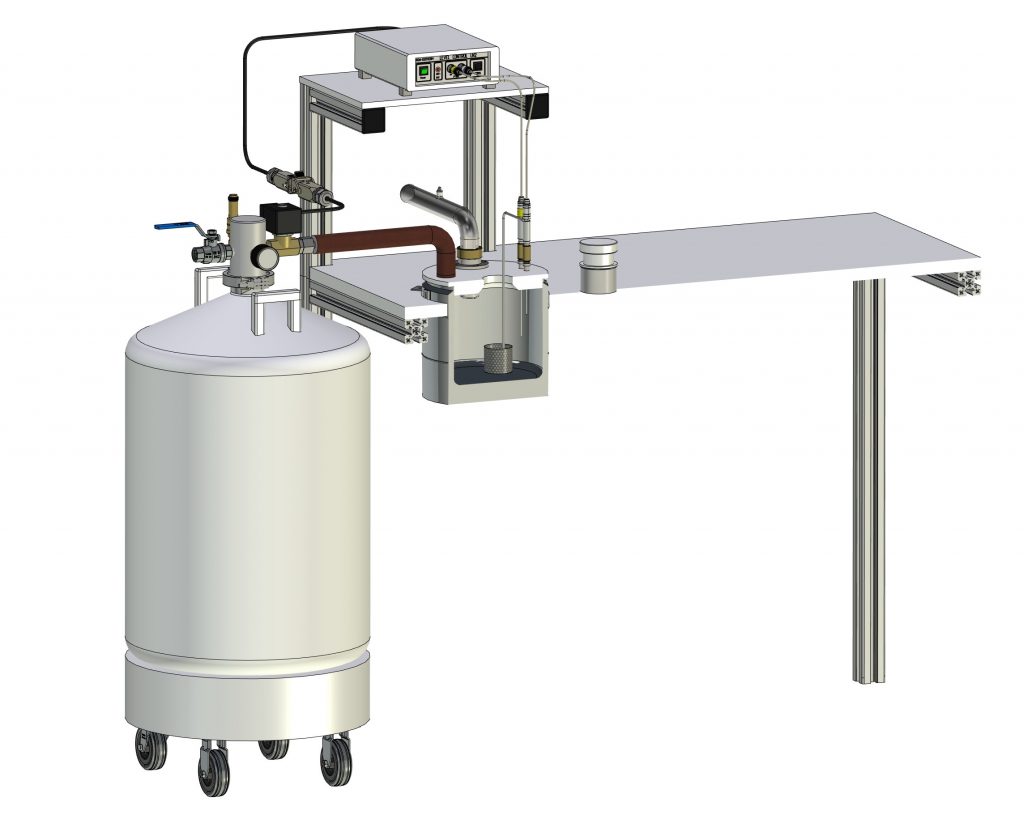

Shrink stands: For professional cold stretching in industry and production, we manufacture shrink stands and liquid nitrogen test stations according to customer specifications. They usually consist of a liquid nitrogen storage vessel, a Dewar vessel, sample holder and optionally an adapted work table. Manual or automatic LN2 filling is possible. Automatic LN2 level control can be integrated on request.

Cold expansion of components of all kinds thanks to custom-made products

Our state-of-the-art production methods enable us not only to offer high-quality series production, but also to manufacture objects specifically to customer requirements. For these custom-made products, we follow your specifications in terms of dimensions, volume, shape or special requirements. Do you need special accessories or equipment adapted to your application for the cold expansion of components? Simply send us an e-mail to info@kgw-isotherm.de or call us on 0721 958970.

Examples of sample baskets / sample holders

Examples of shrink levels for manual LN2 filling

Example shrink stand with automatic LN2 filling

Example shrink stand with automatic LN2 filling and customized work table according to customer specifications

We are also happy to design and manufacture your shrink stand / liquid nitrogen test station according to your own specifications.

Send your request to: info@kgw-isotherm.de

Phone: +49 721 95897-0